产品展厅

|

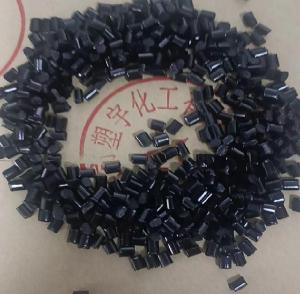

废物容器工用水箱LLDPE 沙特SABIC R50035E 滚塑级

- 品牌:沙特

- 货号:111

- 价格: ¥8.9/千克

- 发布日期: 2023-07-12

- 更新日期: 2026-03-05

产品详请

| 品牌 | 沙特 |

| 货号 | 111 |

| 用途 | 废物容器工用水箱 |

| 特性级别 | 标准级|||高流动||| |

| 牌号 | R50035E |

| 型号 | R50035E |

| 加工级别 | 吹塑级||| |

| 品名 | LLDPE |

| 外形尺寸 | 25 |

| 厂家 | 沙特 |

| 用途级别 | 通用级|||薄膜级|||流延膜专用料||| |

| 是否进口 | 是 |

SABIC® LLDPE R50035EE

Linear Low Density Polyethylene

Saudi Basic Industries Corporation (SABIC)

产品说明:

SABIC® LLDPE R50035EE is a LLDPE copolymer that typically provides good stress crack resistance, rigidity, toughness, gloss and very low warpage. The resin contains UV stabilizer. It is recommended that SABIC® LLDPE R50035EE is grinded before use in rotational moulding applications.

Typical Applications.

SABIC® LLDPE R50035EE is typically used for rotational moulding of large industrial and agricultural tanks, trash containers and chemical shipping drums. Because of its good mechanical properties and low warpage, it is typically used for injection moulding of screw closures, caps and housewares. SABIC® LLDPE R50035EE is UV stabilised; which provides good protection for the final product.

This product is not intended for and must not be used in any pharmaceutical/medical applications.

Typical Applications.

SABIC® LLDPE R50035EE is typically used for rotational moulding of large industrial and agricultural tanks, trash containers and chemical shipping drums. Because of its good mechanical properties and low warpage, it is typically used for injection moulding of screw closures, caps and housewares. SABIC® LLDPE R50035EE is UV stabilised; which provides good protection for the final product.

This product is not intended for and must not be used in any pharmaceutical/medical applications.

物性信息:

| 基本信息 | |

|---|---|

| 添加剂 |

|

| 特性 |

|

| 用途 |

|

| 加工方法 |

|

| 物理性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 密度 | 0.933 | g/cm3 | ASTM D1505 |

| 熔流率(熔体流动速率) (190°C/2.16 kg) | 5.0 | g/10 min | ASTM D1238 |

| 抗环境应力开裂 ( Igepal CO-630, 模压成型, F50) | > 150 | hr | ASTM D1693B |

| 硬度 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 肖氏硬度 (邵氏 D, 模压成型) | 66 | ASTM D2240 |

| 机械性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 抗张强度 | ASTM D638 | ||

| 屈服, 模压成型 | 16.0 | MPa | ASTM D638 |

| 断裂, 模压成型 | 17.0 | MPa | ASTM D638 |

| 伸长率 (断裂, 模压成型) | 590 | % | ASTM D638 |

| 弯曲模量 - 1% 正割 (模压成型) | 420 | MPa | ASTM D790 |

| 弯曲强度 (模压成型) | 13.0 | MPa | ASTM D790 |

| 热性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 脆化温度 | < -75.0 | °C | ASTM D746 |

| 维卡软化温度 | 114 | °C | ASTM D1525 |

| 注射 | 额定值 | 单位制 | |

|---|---|---|---|

| 加工(熔体)温度 | 210 到 240 | °C |