产品展厅

|

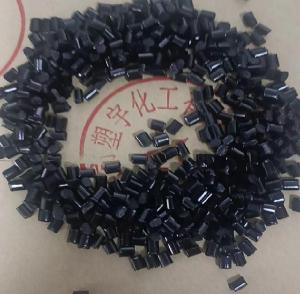

盖子护罩 食品容器外壳PP 基础创新塑料(沙特) QR6731K 注塑级

- 品牌:基础创新塑料

- 货号:222

- 价格: ¥11.5/千克

- 发布日期: 2023-12-12

- 更新日期: 2026-03-05

产品详请

| 品牌 | 基础创新塑料 |

| 货号 | 222 |

| 用途 | 盖子护罩家用货品瓶子食品容器外壳 |

| 特性级别 | 透明级|||抗紫外线|||高滑动||| |

| 牌号 | QR6731K |

| 型号 | QR6731K |

| 加工级别 | 注塑级||| |

| 品名 | PP |

| 外形尺寸 | 25 |

| 厂家 | 基础创新塑料 |

| 用途级别 | 通用级|||电子电器部件|||瓶盖专用料|||薄壁制品||| |

| 是否进口 | 是 |

SABIC® PP QR6731K

Polypropylene Random Copolymer

SABIC Americas, Inc.

产品说明:

Provisional - PP random co-polymer for Injection moulding

QR6731K is specially developed for producing injection molded & ISBM articles with very high clarity at low processing temperatures and also has better impact properties than homo PP counterparts. This grade contains advance clarifier & anti-static agent.

QR6731K has following features:

Typical Applications

QR6731K can be used for clear houseware items, caps & closures, food containers, bottles (ISBM), lids and CD-boxes.

QR6731K is specially developed for producing injection molded & ISBM articles with very high clarity at low processing temperatures and also has better impact properties than homo PP counterparts. This grade contains advance clarifier & anti-static agent.

QR6731K has following features:

- Consistent processability

- Good stiffness

- Exceptional clarity

- Lower energy consumption & less cycle time due to low processing temperatures

Typical Applications

QR6731K can be used for clear houseware items, caps & closures, food containers, bottles (ISBM), lids and CD-boxes.

| 基本信息 | |

|---|---|

| 添加剂 |

|

| 特性 |

|

| 用途 |

|

| 外观 |

|

| 形式 |

|

| 加工方法 |

|

| 物理性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 比重 1 | 0.905 | g/cm3 | ASTM D792 |

| 熔流率(熔体流动速率) (230°C/2.16 kg) | 25 | g/10 min | ASTM D1238 |

| 收缩率 - 流动 | 1.2 到 2.0 | % |

| 硬度 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 洛氏硬度 (R 级, 注塑) | 94 | ASTM D785 |

| 机械性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 抗张强度 (屈服, 注塑) | 28.0 | MPa | ASTM D638 |

| 伸长率 (屈服, 注塑) | 12 | % | ASTM D638 |

| 弯曲模量 - 1% 正割 (注塑) | 1050 | MPa | ASTM D790A |

| 冲击性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 悬壁梁缺口冲击强度 (23°C, 注塑) | 65 | J/m | ASTM D256 |

| 热性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 载荷下热变形温度 (0.45 MPa, 未退火) | 83.0 | °C | ASTM D648 |

| 维卡软化温度 | 127 | °C | ASTM D1525 2 |

| 注射 | 额定值 | 单位制 | |

|---|---|---|---|

| 料筒后部温度 | 190 到 220 | °C | |

| 料筒中部温度 | 190 到 220 | °C | |

| 料筒前部温度 | 190 到 220 | °C | |

| 模具温度 | 15.0 到 40.0 | °C |