产品展厅

|

PEEK 美国索尔维 KT-880 BK飞机应用工业应用连接器密封件

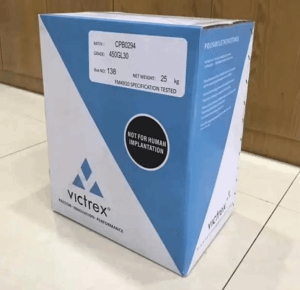

- 品牌:英国威格斯

- 货号:666

- 价格: ¥370/千克

- 发布日期: 2024-06-29

- 更新日期: 2026-02-05

产品详请

| 品牌 | 英国威格斯 |

| 货号 | 666 |

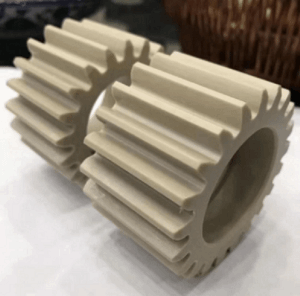

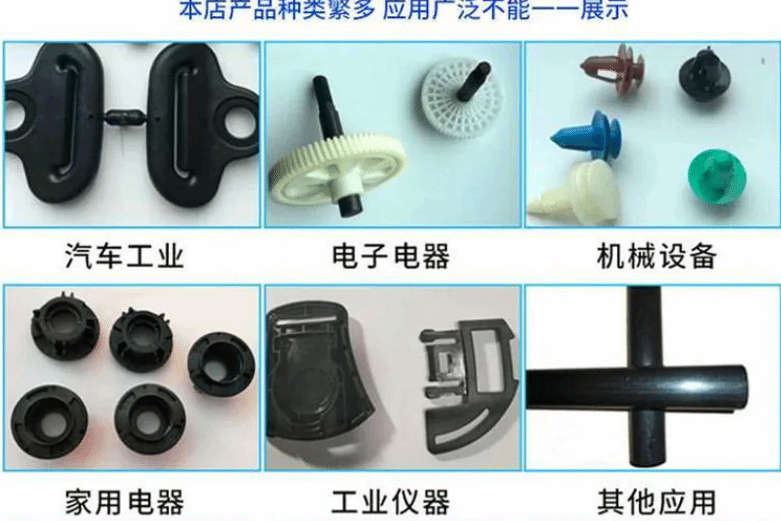

| 用途 | 飞机应用工业应用连接器密封件石油/天然气用品 |

| 牌号 | KT-880 BK |

| 型号 | KT-880 BK |

| 品名 | PEEK |

| 外形尺寸 | 25 |

| 厂家 | 英国威格斯 |

| 是否进口 | 是 |

KetaSpire® KT-880 NL

KetaSpire® KT-880 NL

Polyetheretherketone

Solvay Specialty Polymers

产品说明:

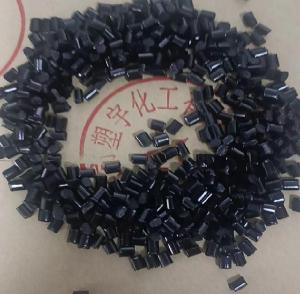

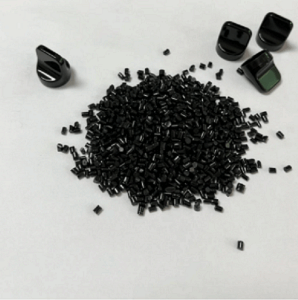

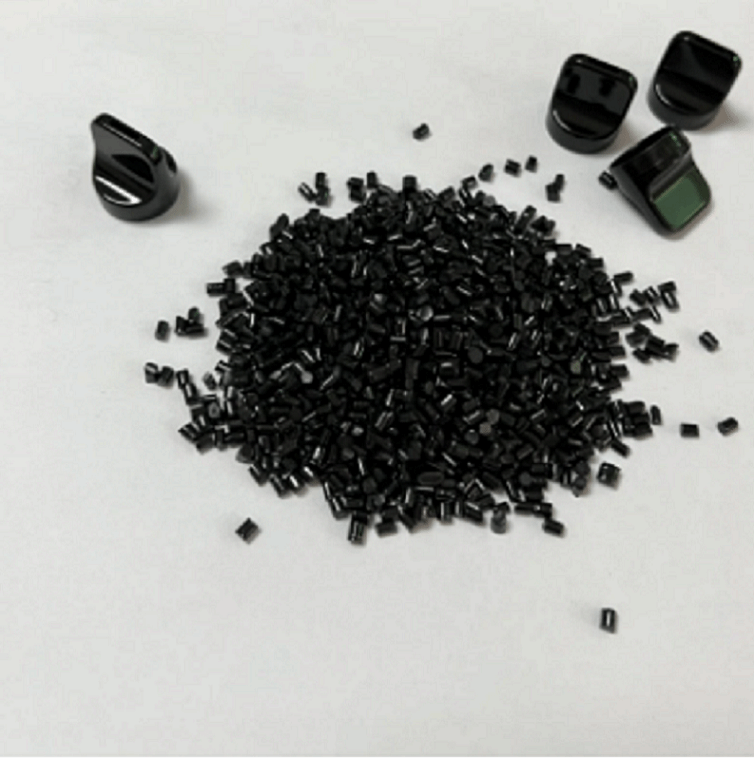

KetaSpire® KT-880 NL is a high flow grade of unreinforced polyetheretherketone (PEEK) supplied in non-lubricated, natural-color pellet form. KetaSpire® PEEK is produced to the highest industry standards and is characterized by a distinct combination of properties, which include excellent wear resistance, best-in-class fatigue resistance, ease of melt processing, high purity and excellent chemical resistance to organics, acids and bases.

These properties make it well-suited for applications in healthcare, transportation, electronics, chemical processing and other industrial uses. KetaSpire® KT-880 NL can be easily processed using typical injection molding processes. This resin is also available as KT-880P in a natural-color coarse powder form for compounding.

A lubricated form of the resin is available as KT-880 in either natural (NT) or black (BK 95). The lubricated version is lightly dusted with calcium stearate (0.1% level) to aid with pellet conveyance in plastication screws.

These properties make it well-suited for applications in healthcare, transportation, electronics, chemical processing and other industrial uses. KetaSpire® KT-880 NL can be easily processed using typical injection molding processes. This resin is also available as KT-880P in a natural-color coarse powder form for compounding.

A lubricated form of the resin is available as KT-880 in either natural (NT) or black (BK 95). The lubricated version is lightly dusted with calcium stearate (0.1% level) to aid with pellet conveyance in plastication screws.

物性信息:

| 基本信息 | |

|---|---|

| 特性 |

|

| 用途 |

|

| RoHS 合规性 |

|

| 外观 |

|

| 形式 |

|

| 加工方法 |

|

| 物理性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 比重 | 1.30 | g/cm3 | ASTM D792 |

| 熔流率(熔体流动速率) (400°C/2.16 kg) | 36 | g/10 min | ASTM D1238 |

| 收缩率 | ASTM D955 | ||

| 流动 | 1.7 | % | ASTM D955 |

| 横向流动 | 1.8 | % | ASTM D955 |

| 吸水率 (24 hr) | 0.10 | % | ASTM D570 |

| 机械性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 拉伸模量 | 3700 | MPa | ASTM D638 |

| 抗张强度 | 100 | MPa | ASTM D638 |

| 伸长率 | ASTM D638 | ||

| 屈服 | 5.2 | % | ASTM D638 |

| 断裂 | 10 到 20 | % | ASTM D638 |

| 弯曲模量 | 3800 | MPa | ASTM D790 |

| 弯曲强度 | 153 | MPa | ASTM D790 |

| 冲击性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 悬壁梁缺口冲击强度 | 53 | J/m | ASTM D256 |

| 无缺口悬臂梁冲击 | 无断裂 | ASTM D256 |

| 热性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 载荷下热变形温度 (1.8 MPa, 未退火) | 160 | °C | ASTM D648 |

| 玻璃转化温度 | 147 | °C | ASTM D3418 |

| 熔融峰值温度 | 343 | °C | ASTM D3418 |

| 线形热膨胀系数 - 流动 (-50 到 50°C) | 5.0E-5 | cm/cm/°C | ASTM E831 |

| 注射 | 额定值 | 单位制 | |

|---|---|---|---|

| 干燥温度 | 150 | °C | |

| 干燥时间 | 4.0 | hr | |

| 料筒后部温度 | 355 | °C | |

| 料筒中部温度 | 365 | °C | |

| 料筒前部温度 | 370 | °C | |

| 射嘴温度 | 375 | °C | |

| 模具温度 | 175 到 205 | °C | |

| 注射速度 | 快速 | ||

| 螺杆压缩比 | 2.5:1.0 到 3.5:1.0 |