产品展厅

|

家电部件PMMA 德国赢创德固赛 CYROLITEG-20HIFLO医用包装

- 价格: ¥180/千克

- 发布日期: 2025-09-09

- 更新日期: 2026-02-05

产品详请

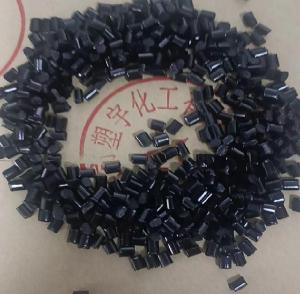

CYROLITE® G-20 HIFLO®

Polymethyl Methacrylate Acrylic

Evonik Cyro LLC

产品说明:

CYROLITE G-20 HIFLO compound is an impactmodified acrylic-based multipolymer for molding and extrusion of medical applications.

Typical properties of CYROLITE® acrylic-based multipolymer compounds are:

The special properties of CYROLITE G-20 HIFLO compound are:

Used for injection molding and extrusion of medical devices, medical packaging, as well as toys and appliance parts.

Typical properties of CYROLITE® acrylic-based multipolymer compounds are:

- excellent chemical resistance to fats and oils

- excellent bonding and welding capabilities

- excellent bonding to PVC tubing

- good impact strength

- good light transmission

- good resistance to EtO, gamma and E-beam sterilization

The special properties of CYROLITE G-20 HIFLO compound are:

- excellent melt flow rate

- good heat resistance

Used for injection molding and extrusion of medical devices, medical packaging, as well as toys and appliance parts.

物性信息:

| 基本信息 | |

|---|---|

| 添加剂 |

|

| 特性 |

|

| 用途 |

|

| 机构评级 |

|

| 外观 |

|

| 形式 |

|

| 加工方法 |

|

| 物理性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 比重 | 1.11 | g/cm3 | ASTM D792 |

| 表观密度 | 0.65 | g/cm3 | ASTM D1895 |

| 熔流率(熔体流动速率) (230°C/5.0 kg) | 10 | g/10 min | ASTM D1238 |

| 收缩率 - 流动 | 0.40 到 0.70 | % | ASTM D955 |

| 吸水率 (24 hr) | 0.30 | % | ASTM D570 |

| 硬度 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 洛氏硬度 (M 级) | 27 | ASTM D785 |

| 机械性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 拉伸模量 | 2550 | MPa | ASTM D638 |

| 抗张强度 (屈服) | 48.3 | MPa | ASTM D638 |

| 伸长率 | ASTM D638 | ||

| 屈服 | 3.6 | % | ASTM D638 |

| 断裂 | 9.5 | % | ASTM D638 |

| 弯曲模量 | 2140 | MPa | ASTM D790 |

| 弯曲强度 (屈服) | 64.8 | MPa | ASTM D790 |

| 冲击性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 悬壁梁缺口冲击强度 | ASTM D256 | ||

| 0°C, 6.35 mm | 59 | J/m | ASTM D256 |

| 23°C, 6.35 mm | 100 | J/m | ASTM D256 |

| 热性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 载荷下热变形温度 (1.8 MPa, 退火, 6.35 mm) | 85.6 | °C | ASTM D648 |

| 维卡软化温度 | 101 | °C | ASTM D1525 |

| 线形热膨胀系数 - 流动 (0 到 156°C) | 9.3E-5 | cm/cm/°C | ASTM D696 |

| 光学性能 | 额定值 | 单位制 | 测试方法 |

|---|---|---|---|

| 透射率 (3200 μm) | 89.0 | % | ASTM D1003 |

| 雾度 (3200 μm) | 6.0 | % | ASTM D1003 |

| 黄度指数 (3.20 mm) | -0.30 | YI | 内部方法 |

| 注射 | 额定值 | 单位制 | |

|---|---|---|---|

| 干燥温度 | 79.4 | °C | |

| 干燥时间 | 3.0 到 4.0 | hr | |

| 加工(熔体)温度 | 193 到 238 | °C | |

| 模具温度 | 48.9 到 82.2 | °C |